Quality Control

Foreword: Stainless steel products have been in production for nearly 30 years since the establishment of new production plants in my country in the 1990s. At the same time, it also shows that my country has nearly 30 years of experience in the production of stainless steel products. Now China's stainless steel production equipment, technology, and technology have greatly grown and improved compared with the 1990s.

Elites in my country’s stainless steel industry began to import and independently develop high-end materials such as duplex stainless steel, super austenitic stainless steel, nickel-based alloys, and Hastelloy alloys from abroad in 2000, and achieved good results, which also reduced a lot of costs for factories in my country and the world. tooling.

Since 2000, elites in the testing equipment industry are also working hard to develop and improve testing equipment, from the past spark spectrometer to the current portable straightness spectrometer, from the past eddy current flaw detection, ultrasonic flaw detection to the current dual non-destructive testing instrument, from the past underwater air tightness testing equipment to the current hydraulic testing equipment, etc., greatly improving the testing effect and efficiency.

Regardless of the industry, in order to have good product quality, in addition to tooling and technical teams, it is also inseparable from a good management team and a set of practical and feasible quality control regulations. At the same time, customers who also need quality requirements.

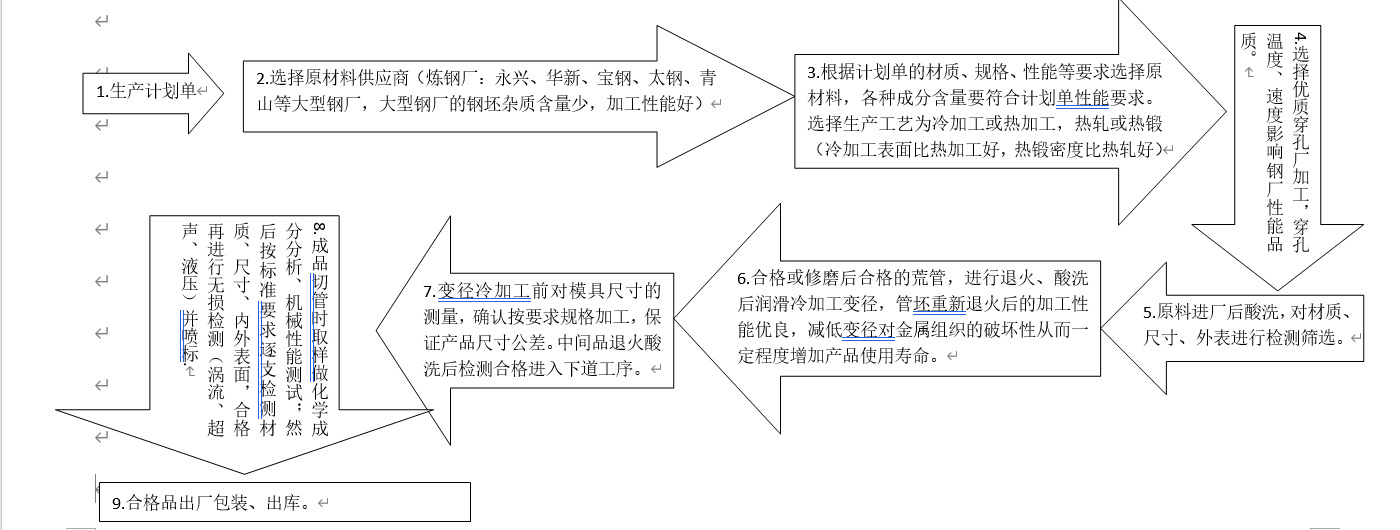

The following flow chart is the quality management program actually operated by our company, and the impact on the performance of the product is noted. Hope to get suggestions from friends from all walks of life to continue to improve!

In the above process, most of the market currency will choose cheap raw materials in 2 to save more than 500 yuan/ton; 3 is the use requirement, the supply and demand sides negotiate according to demand; the currency will choose a low-cost processing plant in 4 to save more than 500 yuan/ton, and the currency will remove 5.6.8 process inspection and grinding costs to save more than 1,000 yuan/ton.

Currency manufacturers double the output at the same time, speed up the annealing speed, and save 500 yuan/ton in terms of gas and cost sharing output. The corrosion resistance and high temperature resistance of stainless steel and alloy materials with insufficient heat preservation time will be greatly reduced, and the service life will be at least half.

ADD:No. 431 Baishui Road, Dushan Village, Yongzhong Street, Longwan District, Wenzhou City, Zhejiang Province

ADD:No. 431 Baishui Road, Dushan Village, Yongzhong Street, Longwan District, Wenzhou City, Zhejiang Province Tel:0577-86927775

Tel:0577-86927775 Mobile:13616615333(Mr. Zhu) 13587870308(Mr. Fan)

Mobile:13616615333(Mr. Zhu) 13587870308(Mr. Fan) Fax:0577-86920920

Fax:0577-86920920 Email:fx@chinafxa.com

Email:fx@chinafxa.com